OEM (Original Equipment Manufacturer) standards are paramount in auto body frame repair, ensuring vehicles return to their pre-accident condition with maintained structural integrity and aesthetic appeal. Collision repair specialists follow a meticulous process that includes accurate damage diagnosis, specialized tools for frame correction, frequent quality checks, and adherence to OEM specifications for primers, paints, and finishes. By prioritizing OEM standards, reputable shops enhance vehicle safety, improve crash performance, and restore both aesthetics and functionality, providing car owners with peace of mind on the road.

In the realm of automotive restoration, adhering to Original Equipment Manufacturer (OEM) standards is paramount for ensuring vehicle safety and quality. This article delves into the meticulous process of auto body frame repair, where every detail matters. We explore how technicians navigate a complex web of specifications and procedures to meet OEM criteria. From understanding industry standards to implementing precise techniques, discover the benefits of this rigorous approach, which ultimately bolsters roadworthiness and maintains the integrity of vehicles undergoing crucial frame repairs.

- Understanding OEM Standards for Auto Body Frame Repair

- The Process of Ensuring Compliance During Repairs

- Benefits and Impact on Vehicle Safety and Quality

Understanding OEM Standards for Auto Body Frame Repair

Understanding OEM Standards for Auto Body Frame Repair

OEM (Original Equipment Manufacturer) standards are pivotal in the auto body frame repair process, ensuring that vehicles return to their pre-accident condition. These standards are meticulously crafted and regularly updated to maintain vehicle safety, structural integrity, and aesthetic appeal. Auto body shops must adhere to these guidelines when conducting any frame straightening or repair work. This involves using specialized equipment and techniques to accurately measure and correct frame misalignments, preserving the original design and performance specifications set by the manufacturer.

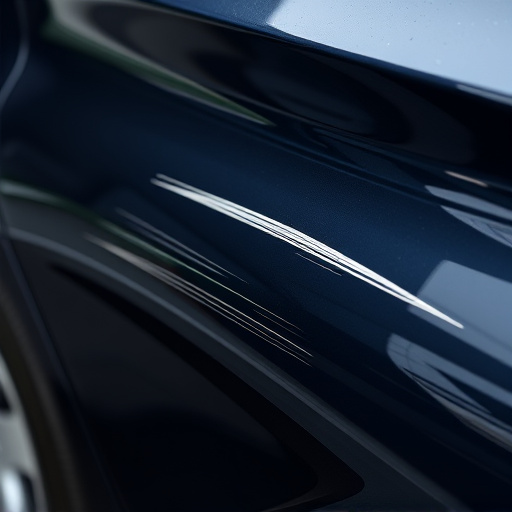

By following OEM standards, collision repair specialists can guarantee that car scratch repairs and other damage are not only visually indistinguishable from the rest of the vehicle but also do not compromise its structural stability. This meticulous attention to detail is what transforms a simple auto painting job into a comprehensive collision repair service, ensuring customer satisfaction and vehicular safety on the road.

The Process of Ensuring Compliance During Repairs

Ensuring compliance with OEM (Original Equipment Manufacturer) standards during auto body frame repair is a meticulous process that involves several stringent steps. It begins with an accurate diagnosis of the vehicle’s damage, where skilled technicians meticulously assess every aspect of the frame to identify areas requiring repairs. This initial phase sets the foundation for the subsequent work, ensuring that only authorized and approved parts are used throughout the entire repair process.

The heart of the procedure lies in adherence to strict protocols designed to maintain the structural integrity of the vehicle. Technicians employ specialized tools and equipment to straighten and align the frame, carefully recreating the original dimensions specified by the OEM. Each step is documented and verified, with frequent quality checks conducted to guarantee precision and accuracy. Moreover, the application of primers, paints, and finishes adheres to OEM specifications, ensuring that the final product not only looks original but also stands the test of time in terms of durability and resistance to corrosion.

Benefits and Impact on Vehicle Safety and Quality

Adhering to OEM (Original Equipment Manufacturer) standards during auto body frame repair is paramount for ensuring vehicle safety and quality. When a car undergoes a frame repair at a reputable car body shop, technicians meticulously follow the manufacturer’s guidelines and specifications. This meticulous process involves precise measurements, proper welding techniques, and the use of high-quality materials that match the original equipment. The benefits are clear: enhanced structural integrity, improved crash performance, and better overall quality. These repairs not only restore the vehicle to its pre-accident condition but also maintain or enhance its safety features, which is crucial for protecting occupants in future collisions.

Moreover, adhering to OEM standards impacts the overall driving experience. Auto glass repair, a critical component of frame repair, ensures that the vehicle’s structure can withstand forces during an accident while providing clear visibility for safe operation. Vehicle bodywork, when expertly repaired according to these standards, not only revitalizes the aesthetics but also ensures that all components work in harmony. This attention to detail and adherence to OEM protocols is what distinguishes a quality car body shop from its competitors, ultimately giving owners peace of mind on the road.

In conclusion, adhering to Original Equipment Manufacturer (OEM) standards during auto body frame repair is paramount for maintaining vehicle safety and quality. By understanding these stringent guidelines and employing meticulous processes, professionals ensure that repaired vehicles meet or exceed their original specifications. This not only preserves the integrity of the vehicle but also reassures owners of a secure and reliable driving experience.